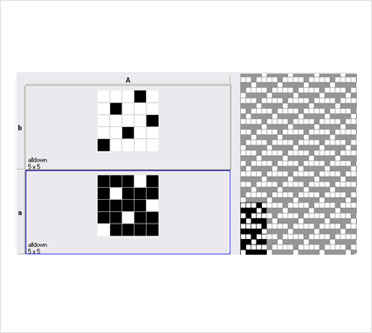

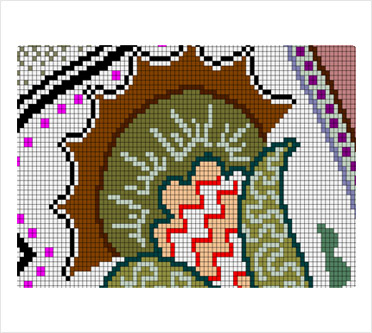

Design Editing in Grid

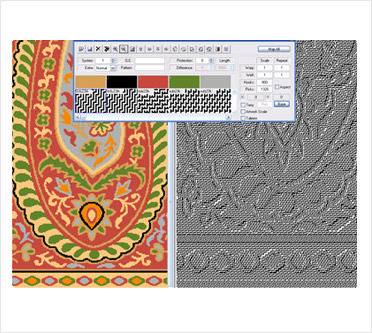

The Jacquard design software in CAM offers precise editing tools for varying Warp and Weft densities. Designers can use freehand tools, geometric shapes, bezier curves, auto-outline, and bandhani patterns for accurate design creation. Multiple UNDO/REDO options and variable brush sizes ensure flexibility and precision.

The jacquard CAD software features color shielding to protect intricate designs, and copy-paste capabilities for efficiency. Editing supports different repeat types (straight, cross, mirror), and the Navigator tool simplifies design navigation in Zoom/GRID modes.

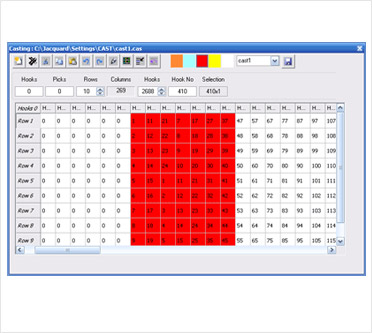

Compatible with Jacquard Fabric Simulation Software and jacquard loom design software, it integrates seamlessly with production for real-time visualization and detailed fabric design.